Manufacturing

Since our founding, we have used heat to provide people with healthy and comfortable lives. However, even a small defect in heating equipment can cause a major accident. As a comprehensive manufacturer of heat and energy equipment, we have rigorously practiced "quality-oriented manufacturing" at our R&D and production sites, placing top priority on the safety and security of our customers. Committed to engaging in the best manufacturing practices, we focus on the following two things.

Integrated production

To ensure high quality, we integrate all processes, from design to processing, assembly, inspection, and shipping.

Self-sufficiency

To improve quality, we emphasize in-house manufacturing of our production equipment.

Role of the manufacturing division in new product development process

- 1Front-loading

-

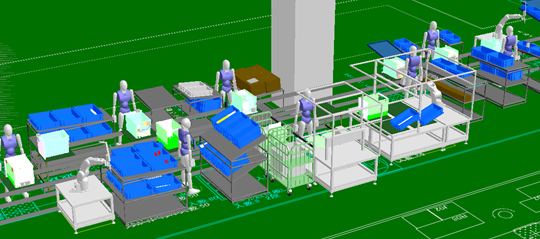

- Our manufacturing division participates in the new product development process from the very beginning. Previously, the product development division was involved only after the product design was completed, and any problems with production start-up were fed back to that division as they arose. However, this process was mainly useful for making minor corrections and did not allow for major improvements. The introduction of front-loading has allowed us to fundamentally rethink our manufacturing methods and develop products with much higher productivity than in the past.

Team discussion

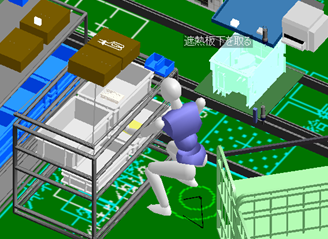

When incorporating quality and productivity, we use front-loading to build an assembly line in virtual space that is similar to reality, allowing us to conduct highly accurate assessments.

Flow-line optimization

Layout design

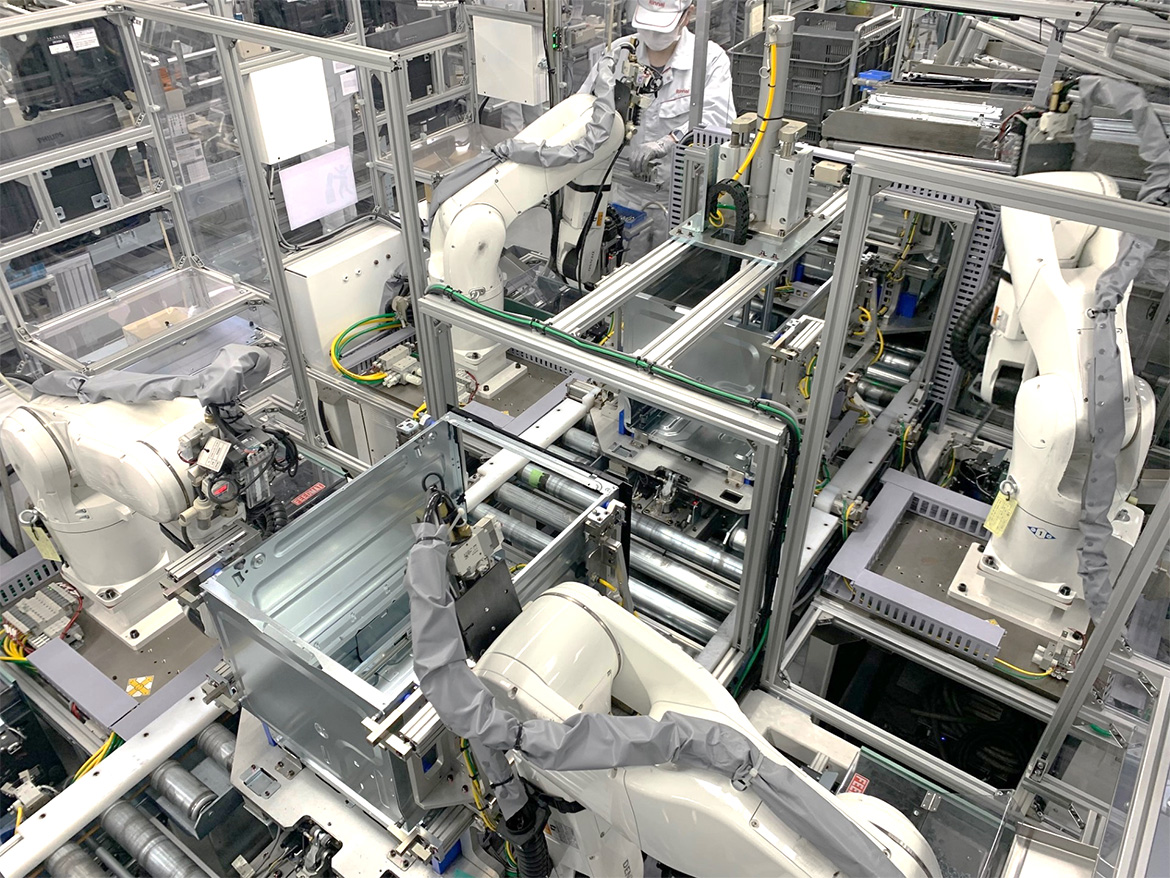

Thanks to collaboration between the product development division and the manufacturing division to address production issues at an early stage, we were able to make products designs allowing easy automation by robots.

-

[Success stories]

SK stove (Mytone) assembly line (mass production started in 2018)

Significant improvement in screw-tightening automation rate

- 2Production start-up

-

The manufacturing division collaborates with the production engineering division to engage in production design, manufacture equipment (automation equipment, FP equipment, inspection equipment), and produce software (information systems) in-house.

Assembly line production design

We design and manufacture assembly processes for new products. Making full use of IE improvement methods, we will create a production process free of excess, waste, and irregularity.

Full-scale implementation of "pre-supply/pre-preparation" process

Pre-supply/pre-preparation: Process in which parts are supplied ahead of the operator, allowing the operator to pick up the parts ahead of assembly.

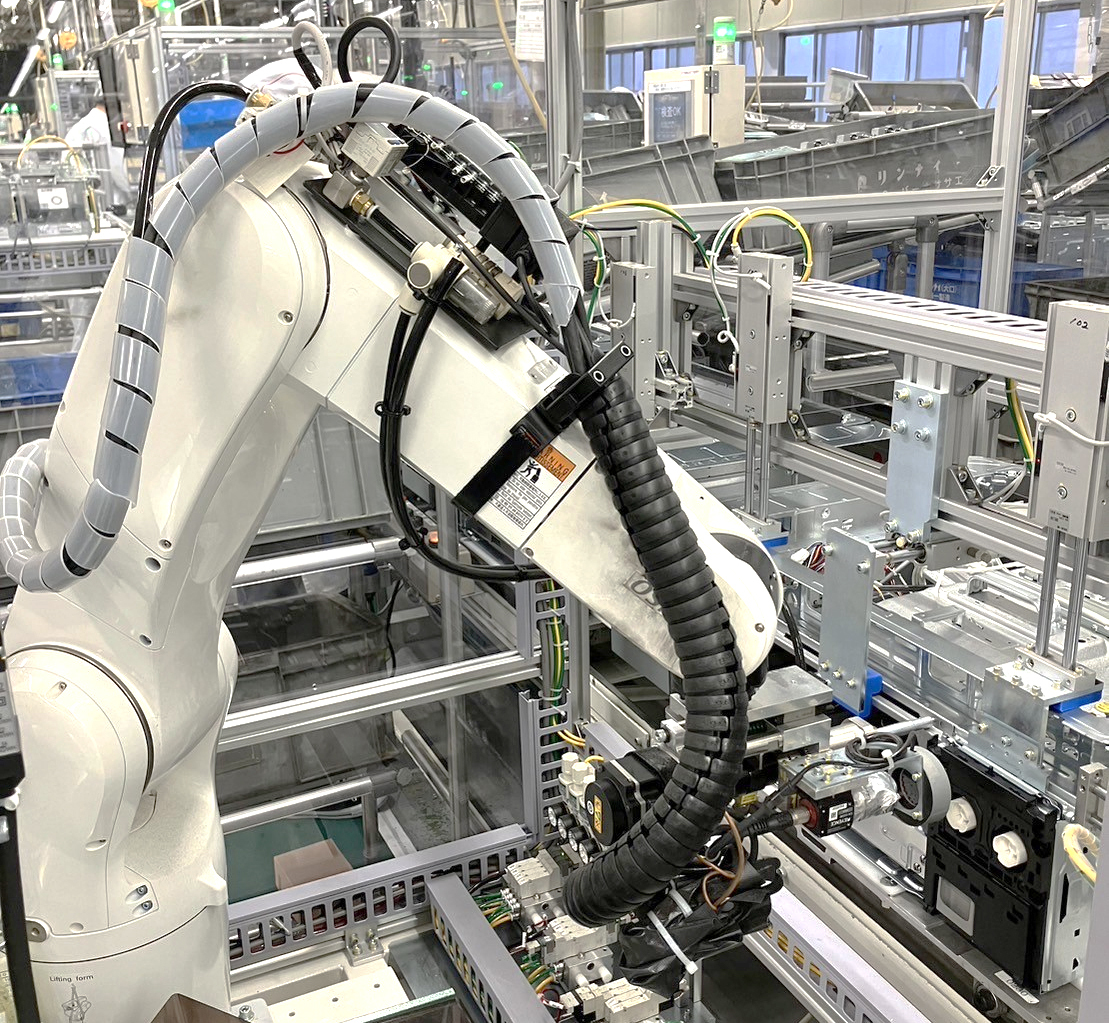

Introduction of automated equipment

We use industrial robots to automate assembly processes, such as screw tightening and parts setting. The robots are connected to each other via a network to enable multiple robots to collaborate.

Automatic parts set

Unmanned inspection machines

Collaborative robots

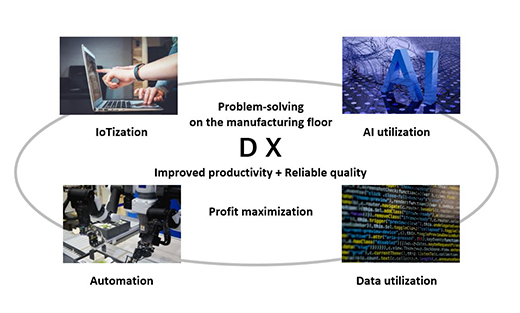

DX

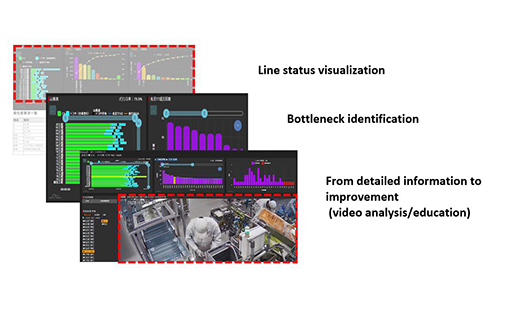

We established a system to automatically collect various information from production sites and respond quickly.

We are building a system that allows us to focus on improvement activities.