Case Study – Production Factory Deployment

The Production Engineering Headquarters conduct R&D on processing technologies, material and analysis technologies, simulation technologies, and other core production technologies, with the aims of entering mass production more quickly and improving productivity. It has developed new machining and inspection equipment and deployed them at each of our production plants to ensure optimal parts machining and assembly without defects.

-

Design

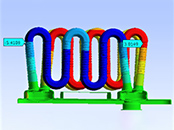

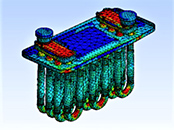

From the perspective of production design, we propose concepts for new parts, perform basic design, and test prototypes in order to enter mass production of new products at an early stage.

-

Parts processing

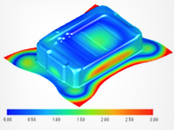

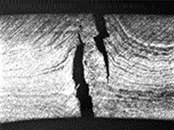

Materials used in gas appliances are exposed to challenging environments, such as combustion heat and gases, water quality (that differs around the world), extremely hot water, boil-over spills, and detergents. We develop materials and processing technologies to withstand these environments, as well as various performance evaluation technologies. We are also developing new construction methods to reduce manufacturing costs and achieve high design and durability.

-

Assembly

Our aim is to improve quality by automatically judging good products based on inspection images and conducting inspections more accurately and efficiently.